|

|

[ 1

I 2 ]

GMB BEARING

GMB bearing is machined and assembled by the up-to-date

bearing manufauring facilities from forging of raw materials to

inspection and life test.

GMB's unique process quality control system and fully automated

manufacturing equipment will not allow non-conforming products to be

transferred to the next process.

Deep groove ball bearing, Water pump bearing, Needle roller bearing.

GMB bearing used for various automobile, electric motors, machine tools

will open another staage for further development of precision machine

industry.

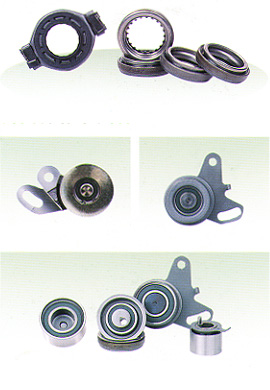

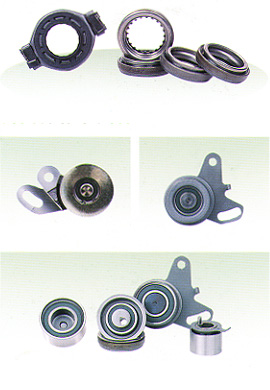

TENSIONER IDLER

We have the best

manufacturing facilities and product quality control system to secure

the complete high quality, depending on the accumulated experience

and engineering as well as a spirit of challenge to create a new value.

On them, we produce TENSIONER & IDLER PULLEY BEARING as a main

components of

a car which has a complex lay-out function to deaign engine's compact,

light,low noise

and high-speed, with the international engineering capability of GMB

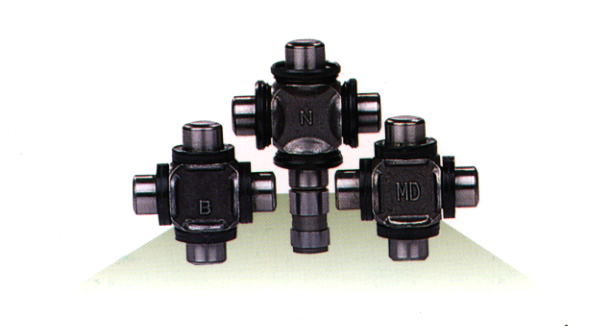

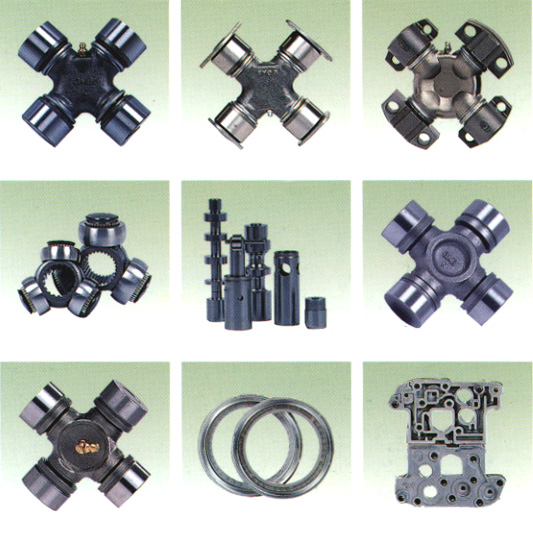

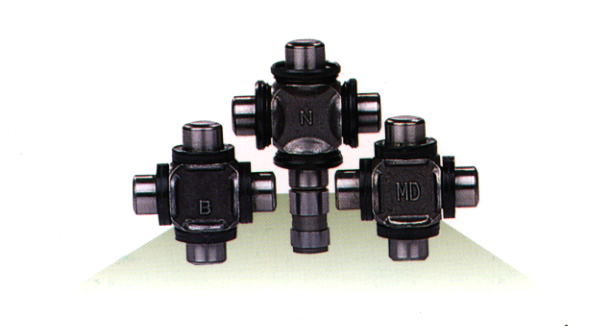

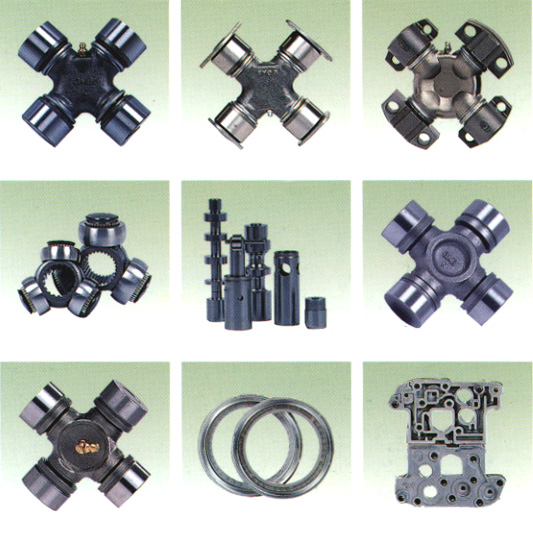

UNIVERSAL JOINT

POWER TRAIN. A main

component of the human-mechatronics producing a complete harmony between

a human and a car, which is produced and supplied in the standardized

assembly process and the detailed inspections through all processes to

maintain

optimums, reducing the vibration of a car and rising the power in order

to reach at the highest quality of precision, high unity, and the

highest durability, Furthermore,

We do our best of continuous technological innovation and R & D to

make a car

civilization better in future.

WATER PUMP

A complete harmony of

vehicles and engines resulting

from the GMB high precision mechanism.

It will be secure of lowering the fuel consumption and nose, and of

expanding the running life of engines under any condition.

With it, a working process of the total assembly lines will be total

assembly lines will be

standardized to maintain the highest optimums of a car, and it is

through a complete

inspection system between processes that a quality system will be

reached starting the design process.

We are trying to reach at the principle of fault free and going to

achieve the first quality and

stabillity in the world so we can make a new history in precision

machine manufacture.

|

|